B041MEN

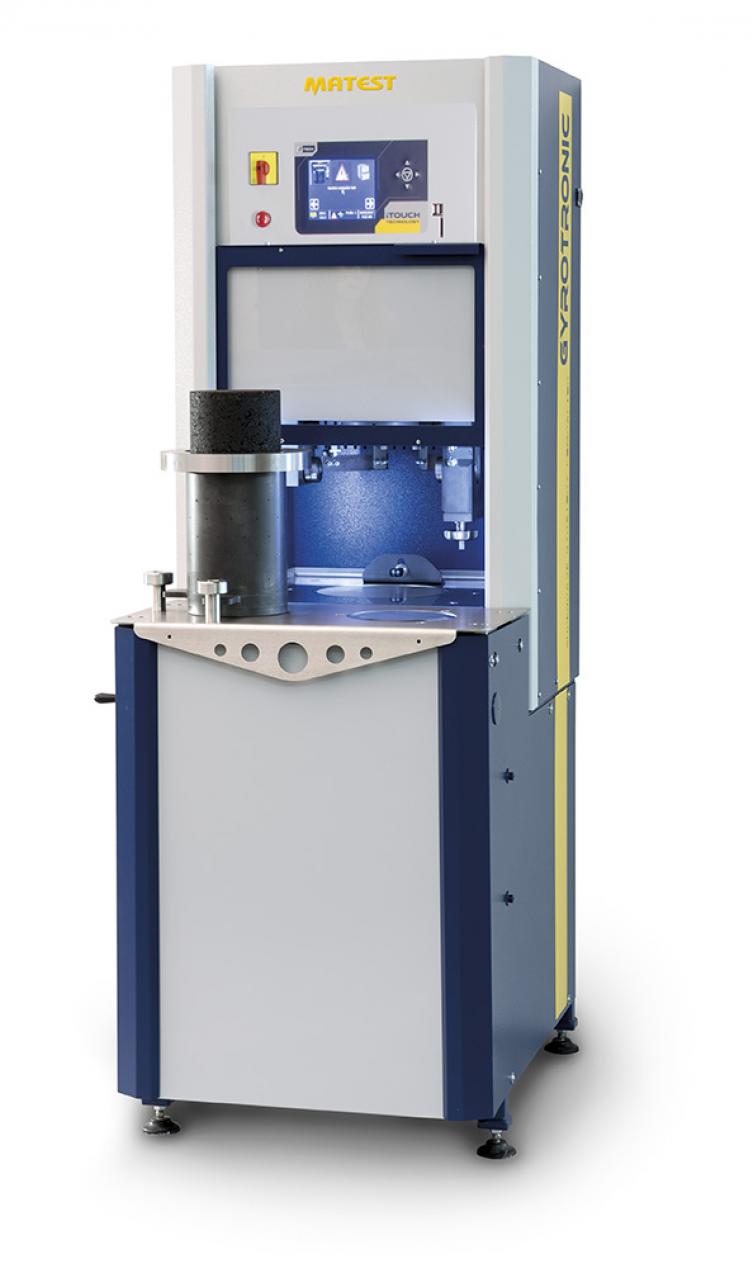

Gyrotronic Superpave Gyratory Compactor – EN Standard

(

Asphalt

)

The Matest Gyrotronic Superpave Gyratory Compactor – EN replicates real field compaction to accurately assess the performance of asphalt mixtures. Fully automatic, it combines rotational motion and controlled vertical force, applied by a servo-regulated electro-pneumatic system. A rigid steel frame ensures exceptional angle stability, while a precision eccentric mechanism maintains a constant gyration angle of 0.82°, as required by EN 12697-10 and EN 12697-31.

Height is continuously tracked by a linear transducer, and cold-mix emulsions can be tested using the dedicated perforated mould. The intuitive touch-screen interface provides fast parameter setup, real-time data acquisition, graphics and file export.

LAN/Internet connectivity enables remote diagnostics and software updates, while the onboard memory includes USB and SD ports. Supplied calibrated and ready to operate, the unit supports advanced volumetric and mechanical analysis for high-quality asphalt mix design.

Запрос информации о продукте